I've been having a blast with my new hobby - 3D Printing. I've only been printing for about 9 months but my kids and I are having fun which is what matters.

I've been having a blast with my new hobby - 3D Printing. I've only been printing for about 9 months but my kids and I are having fun which is what matters.

I've been using an HP Sprout PC (full review of the Sprout coming soon) along with a Dremel 3D Printer to build stuff with the boys. The Sprout is interesting not just for it's form-factor and Intel RealSense camera but also its 3D scanning platform. I don't have the platform yet but I have one on order. The idea is that the platform rotates the object to be scanned while the Intel 3D camera gets depth information, along with structured light scanning and a second 14 megapixels camera capturing textures. I've got a video here showing the scanning of a teapot. The scans are not perfect, but the scans are a great kickstart for a new project. I'll cover the 3D scanner and HP Sprout more in another separate post, but I will say that it's very fast (an i7!) with a great touchscreen AND a projector with touch mat, so it's effectively a multimonitor multitouch two screen system. My wife has been "scanning" bills with it, while my boys have been spending many hour making StopMotion videos with their LEGOs.

Dremel 3D Printer

In this post I want to focus on the Dremel 3D printer. I've used a Printrbot for several months and have been very happy with it. It's definitely a hobbyist/hacker machine. Many people choose to build a Printrbot from a kit, not just to save money, but also to (forgive me) build owns own lightsaber.

The Dremel feels more Consumer, or at least, Prosumer. While the Printrbot required a few hours before I was printing a basic object, with the Dremel I was printing within 15 minutes. No joke. Now, for a non-techie that might be an hour or so, but seriously, I unboxed it, leveled the bed, and pressed Build on the touchscreen.

The Dremel uses PLA and a non-heated bed. There's special Dremel 3D Build Sheets, essentially like "BuildTak," that adhere to the bed. You also should (you don't have to, but it's easier) use Dremel's filament. Why?

Let's unpack a few things here. No heated bed, use their filament, and just PLA. For the pro this might give you initial pause. But let me tell you - the prints are amazing. Here's a close up.

This is the very first print. The filament runs at a much hotter temperature than I'm used to with PLA. They run it at 220C when I use 180C on my Printrbot. In the Dremel Reddit AMA they mentioned that all this is to maintain "it just works" quality, and I can say now after having printed about 40 things with the Dremel and am currently on my 4th Filament roll that it does just work. I have had one iffy print in 40 prints and it's still usable. Their build tape REALLY works, even with large surfaces. I have had no peeling up or warping.

Here's a video of the Dremel in action.

And here's a pencil holder that turned out great.

My 7 year old and I wanted to see how far we can push this printer so we are currently trying to print a Crossfire 2 Quadcopter. This is a complex print with over a dozen parts in tight tolerances that will be put under stress (assuming we get it to fly) so it seems like a reasonable test.

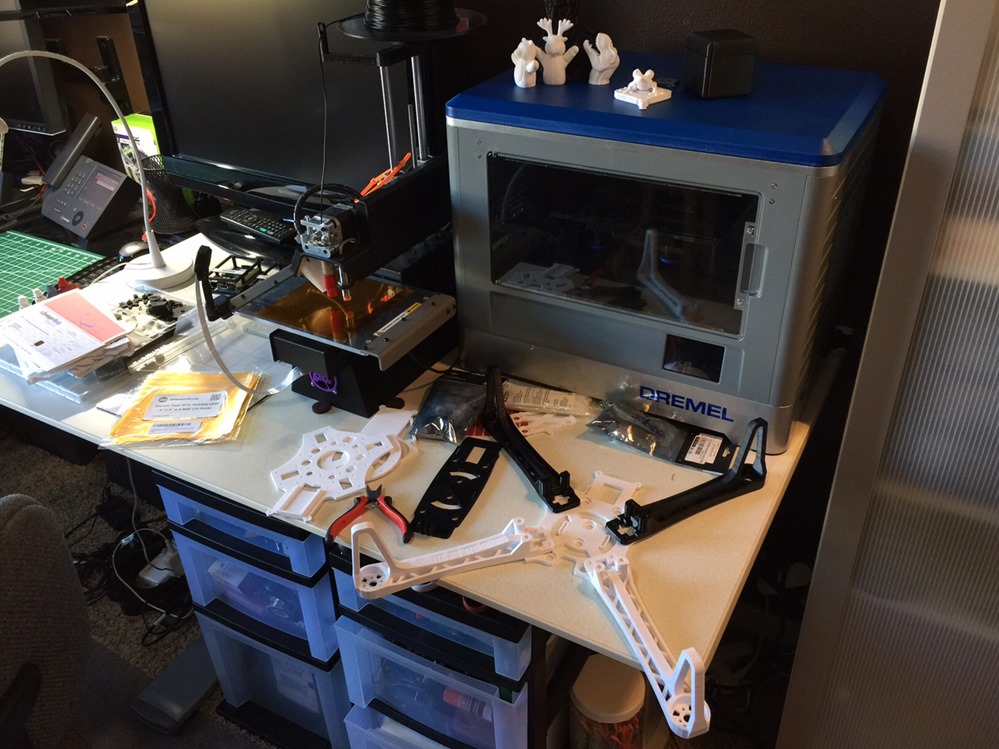

So far it's coming out nicely and it's huge. The Printrbot Simple Metal is a great printer with a 6"x6"x6" bed but this is where I really appreciate Dremel's 9"x5.9"x5.5" bed size. You can see the quadcopter's legs below. We're printing two in black so we can tell the copter's front from its back.

In this pic you can see the size difference between the Printrbot and the Dremel. The Dremel is like a small microwave. It's enclosed (which is really nice) and maintains its inner temperature nicely during the print which may be why it hasn't needed the heated bed. At 220C and a very warm inner environment I have had no peeling or sticking issues.

The last quirk about the Dremel that was interesting was that you don't get direct access to it from any app and you can't send it gcode (raw instructions). Instead you use their Dremel all to import STLs and then export them to their g3drem format. This concerned me originally, but opening the g3drem file in notepad shows that it's simply gcode with a small thumbnail image prepended in front. This is a nice touch as the Dremel has a small color touchscreen that shows you what you're going to print.

The standard workflow is simply:

- Design or download an STL however you like.

- Optional: If it needs supports, open in Meshmixer and add supports. Click Send to Printer.

- Dremel 3D opens the exported (with supports) STL file. Click Build to save a g3drem to an SD card.

- Take the SD card to the Dremel, click Build on the touchscreen and print!

I continue to use both the Printrbot and the Dremel day to day. I've added/upgraded the Printrbot with a heated bed so I can print ABS plastic as well as PLA, but I've turned to the Dremel as my "daily driver" due to its rock solid reliability. I can definitely recommend the Dremel as a good beginner 3D printer for families, classrooms, or hobbyists. While it's not hackable, it's not meant to be. It Just Works and does exactly what it's advertised to do.

I'll blog in the future as our quadcopter build continues!

3D scanning with #SproutByHP. @hp. Really insane.

Related Links

- The Basics of 3D Printing in 2015 - from someone with 16 WHOLE HOURS' experience

- 3D Printer Shootout - $600 Printrbot vs. $20,000 uPrint SE Plus

Disclosure of Material Connection: HP sent me this Sprout and Printer in the hope that I would review it on my blog and because I've been talking actively about 3D Printing and Maker Culture. Regardless, I only talk enthusiastically about products or services I would use and think you would find useful. I am disclosing this in accordance with the Federal Trade Commission’s 16 CFR, Part 255: “Guides Concerning the Use of Endorsements and Testimonials in Advertising.

Sponsor: Big thanks to my friends at Raygun for sponsoring the feed this week. Only 16% of people will try a failing app more than twice. Raygun offers real-time error and crash reporting for your web and mobile apps that you can set up in minutes. Find out more and get started for free here.

© 2015 Scott Hanselman. All rights reserved.